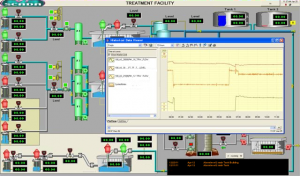

Integrated HMI tools help a MA water utility get the most from historical data.

Serving roughly 35,000 people, the Town of Natick Water/Sewer Division remotely monitors two water reservoirs, 32 sewer lift stations and two drinking water treatment plants. In 2008, the utility found itself with an aging monitoring & control system that was becoming increasingly difficult to use and maintain.

Natick’s Consultant Engineer, Greg Eldridge, VP at Haley and Ward, cadabrought in Andrew Ian of IAN Technology Solutions* to create a new system using VTScada software. This HMI product was able to communicate with existing PLCs and RTUs.

Most importantly, it was a single integrated package that included critical features such as historian, report generator, remote access and alarm dialer. In this article, Natick’s Anthony Comeau and integrator Andy Ian discuss how the new system is helping operators and managers more effectively spend their limited time and budget.

What is SCADA?

A supervisory control and data acquisition (SCADA) system typically includes these elements:

- Remote monitoring & control devices to collect data and control equipment at remote sites. Natick’s original system used a combination of Modicon Quantum/984 Programmable Logic Controllers (PLCs), Momentum PLCs and Bristol Babcock Remote Telemetry Units (RTUs).

- A communication network to relay commands and bring back process data. Natick used VHF radios with store-and-forward repeaters to reach isolated areas. A master PLC at the water plant polled sites to retrieve data.

- An historian to store collected process data.

- Human machine interface (HMI) software to provide operators with a graphic representation of the process.

- A reporting package to automate the configuration of state reports on a monthly and yearly basis.

- An alarm management system to alert on-call personnel and emergency responders to system problems.

The Challenges for a New SCADA System

Anthony Comeau, Water Treatment Plant/GIS Supervisor with Natick’s Water/Sewer Division had several goals for the project. “First, we wanted to find a full-function SCADA system that did not require additional staff to manage.” This included functionality such as trending, remote access (including smart phones) and highly-customizable security privileges. “Secondly, the end product needed to be simple enough that the whole treatment staff could use it. Finally, we needed a SCADA product that worked with the latest technologies.”

New Integrator, New HMI Software

Andy Ian of IAN Technology Solutions started working with Natick in 2008. “Greg Eldridge of Haley and Ward Engineers brought me onto this project,” says Ian, “Greg has been the town’s consultant engineer for years. I have worked with him on many projects. We have been familiar with Trihedral’s VTScada software since the Y2K days. He originally brought me in to fix the town’s radio problems. They were having a lot of communication errors. I performed a radio study and reconfigured their system.

Then they asked me to work on their PLC issues and finally I was contracted to replace the whole HMI.” Both Ian and Eldridge were already working with VTScada. “Several of Haley and Ward’s customers use VTScada. He was the one who introduced it to the town. The customers like the ease of use, the reliability and the integrated features.”

Project Timeline

“In late 2009, I started adding VTScada,” Ian continues, “Initially, I just duplicated the functionality of the previous system and then I began to improve upon that. Since then there have been a lot of additions and changes to the PLCs along the way. We replaced some older RTUs with Momentum PLCs and made changes to the plant functionality.”

By 2010, the new system was essentially complete. “It went fairly smoothly. We tested everything as we went along. Then we ran the new and old systems side-by-side for several months,” says Ian, “They wanted to have confidence in the new system before they shut down the old one.”

New Features

Trending – “The new system has been a very good investment for us,” says Comeau, “One of the biggest improvements over our previous system is the trending screens. Everything has a trend. This allows us to quickly access enormous amounts of information for troubleshooting system failures and reducing costly repairs.”

Andy Ian concurs. “With the old system, it was difficult for operators to get the historical information they needed. VTScada is much easier to use with more features for trending, reporting and viewing alarming history. For example, operators can now easily construct trends based on specific sets of values and then save them. Theycan add notes to the Historical Data Viewer so other operators can look back and see what was happening at a particular time. They can track PLC communication failures. They can see when the last backwash was and how long it took. Also, other HMI packages don’t keep process data for that long.” VTScada is capable an almost unlimited amount of historical data.

Highly Customizable User Accounts – Though the new SCADA application encompasses both water and wastewater, each user’s access to specific functionality can be tailored to their responsibilities.

Alarm Dialer – “The integrated alarm dialer is a big benefit for us,” says Comeau. When an alarm goes unacknowledged, VTScada can notify personnel by email, pager or voice-to-speech phone call. Authorized users can even login and acknowledge alarms over the phone. VTScada also supports rosters of operators and managers that the alarm dialer will call sequentially until an alarm is acknowledged. “They configured several different rosters of 8 to 10 people,” says Ian, “The alarm dialer automatically switches between the rosters depending on who is on call. That is a handy way of doing things.”

Remote Access – Authorized utility personnel can remotely access the system via Internet Client or Smartphone. “Having remote ac-cess saves a tremendous amount of hours and resources,” says Comeau.

The Future

The completed system is scalable to accommodate continued growth. “We may add more remote water sites,” says Ian. “We also hope to finish upgrading the control panels for the second water tank this spring.”

“We recently started creating customized reports using the VTScada reporting tools. Shortly, operators will be able to automatically generate chemical usage reports for each station.” When asked what he is pleased about the most, Comeau replies, “Having a system I can trust, fully understand and control.” He has this advice for utilities that are planning to acquire or replace a SCADA system, “Find a good integrator and retain his services for a few years.”

| Try It For Yourself Download the 90-day Trial |

For More Details Andy Ian: 603.548.0181 andy.ian@wright-pierce.com www.wright-pierce.com |

Images used with permission.

*IAN Technology Solutions is now Wright-Pierce