Q&A With Clermont County, Ohio

Clermont County is one of the fastest growing counties in Ohio, with a population of 197,363. The Clermont County Water Resources Department (WRD) recently recognized the need for a new SCADA system. Bryan Gruber, Maintenance Supervisor for Clermont County WRD, describes their process for choosing and developing a new SCADA system.

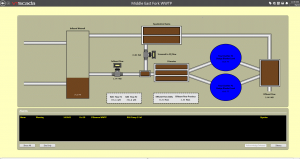

Gruber is responsible for all mechanical and electrical maintenance activities at the 105 wastewater lift stations, 8 wastewater treatment plants and 2 wastewater equalization basins. As the former Lead Systems Technician, he was responsible for implementing this new SCADA system into the County’s operations.

Can you briefly describe the system you were using before VTScada? – “We had a landline based telemeter/dialer system that would send any 1 of 5 critical alarms to a dot matrix printer at one of our 24-hour plants. The plant operator would then initiate a phone call to the response personnel as needed.”

What were some of the issues of that system? – “Plant Operators have other duties within the plant and cannot always man the printer resulting in late calls or even missed alarms in some instances. Landline monthly cost was [three times the cost per site of a] new cellular based system. Lack of ‘real data’ from the telemeter system.”

How did you first find out about VTScada? – “In my former position of Systems Technician, I was tasked with finding something better, expandable and user friendly. Not sure where I first heard of VTScada, possibly a trade publication or during internet research. I contacted Patrick Cooke and he was very helpful.”

Describe the selection process. – “We had demonstrations from various vendors. [We downloaded] a demo of VTScada and experimented with it.”

What was it that led you to choose VTScada? – “Operator friendly, ease of integration and expandability, multiple packaged drivers, redundancy, cost and excellent support.”

When did installation begin and end? – “April to December, 2012”

Describe the design process? – “Fairly simple, we wanted a secure VPN, Static I/P addressing and expandability. Basically we have created a wireless Ethernet network.”

Describe the testing process. – “Cellular Signal Study, VPN creation and testing, alarm testing.”

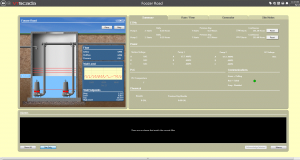

Describe the final system. – “[There are] 114 remote wastewater sites monitored locally by Allen Bradley Micrologix 1400 PLC’s, each connected to a Sierra Wireless GX400 cellular radio. Main server is running VTScada software. All on a VPN with dedicated Static I/P addresses for each site. Numerous security protocols are in place such as SSL encryption, firewalls, and password protection. Multiple redundancies and power sources are in place. Voice, email, and text alarms are sent via landline and/or internet client emails.”

What can you do now that you couldn’t do before? – “Retrieve real time data, well levels, flows, pump starts, runtimes, rainfall rates and totals. [We can also] access and program PLC’s from remote locations, even from home, and make real time process changes.”

What are you most proud of? – “The stability and accuracy of the system as a whole.”

Did any of you take any training? – “Yes, we sent two employees to the 4-day VTScada Training.”

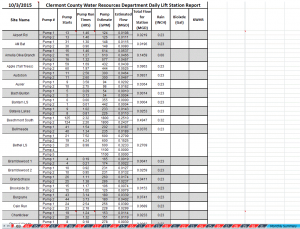

How has VTScada helped you to increase efficiency? – “Being able to see how our process operates has allowed tremendous gains in efficiency. To date we have eliminated over 500,000 pump starts per year. This is a snowball effect which eliminates mechanical movements as well, such as check valve operations, etc., which leads to decreased wear and tear on pumps and equipment and less emergency repair. By monitoring well levels real time and making process changes on the fly, we have reduced after hours call outs by over 60% as well. We receive daily pump start/runtime/flow and rainfall reports allowing us to identify issues such as clogged pumps or infiltration as they arise and make corrections to our wastewater system before they become critical repairs.”

What can your people do in-house? – “We do all PLC programming, VTScada programming, report generation, mostly everything. When we have trouble Trihedral Support is excellent.”

Do you use VTScada Internet Connectivity? – “Yes all the time.”

Does the SCADA system feed data to other resources? – “XL Reporter.”

How does your system handle redundancy? – “We have a main server connected to a wired broadband connection. At the main server, we also have a cellular based broadband connection available which automatically activates if the wired connection fails.”

“This is all backed up by an emergency generator. We also have two local remote client servers at separate locations each with a generator and independent internet connections that can assume remote site polling if the main sever were to fail.”

Ease-of-use features that were beneficial? – “The interface and programming of VTScada has a learning curve like anything else, but once learned, it is much simpler and quicker to deploy than other similar software.”

What are your plans for the future? – “[We plan to] build out our instrumentation at the remote sites in order to retrieve additional helpful data. [We also want to] plan and deploy a similar system to our water distribution system.”

“VTScada has changed the way we operate. The insight into our operations is invaluable, simple to deploy, and the Trihedral Support network is TOP NOTCH.”

| Try It For Yourself Download the 90-day Trial |

Download the Q&A as PDF |

Visit Clermont County Water Resources Department’s Website

Images used with permission.