A New York integrator compares hosted and traditional SCADA

The typical SCADA system is a diverse collection of hardware and software spread over a large geographical area. Many utilities, especially those without dedicated IT departments, simply cannot afford the cost of purchasing, configuring, and indefinitely maintaining this level of infrastructure. However, the need for reliable process monitoring, control, and analytics is growing sharply for utilities of every size. In recent years, hosted or ‘cloud-based’ systems, are offering ut ilities instant turnkey access to leading-edge SCADA features on a subscription basis with very little upfront hardware cost. In this article, Tony DeFranco of Colacino Industries, describes how they decided to develop their cloud-based SCADA solution and how it has proven to be a successful alternative to their traditional SCADA products.

ilities instant turnkey access to leading-edge SCADA features on a subscription basis with very little upfront hardware cost. In this article, Tony DeFranco of Colacino Industries, describes how they decided to develop their cloud-based SCADA solution and how it has proven to be a successful alternative to their traditional SCADA products.

Traditional Vs. Cloud-Based SCADA

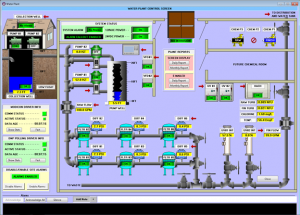

In a standard SCADA system, monitoring and control devices such as Remote Telemetry Units (RTUs) or Programmable Logic Controllers (PLCs) collect process data in the field and send it over some kind of network to a server. A software application archives this information and makes it available to operators and administrators via screens, trends, and reports. Authorized users can also use the system to send commands to remote sites to perform control actions. The devices, radios, computers and software licenses are the property and the responsibility of the utility or other end user. In a hosted SCADA solution, a third-party provider maintains a single application that performs parallel monitoring and control of multiple end-user processes. Customers can log on to their accounts from anywhere using PCs, smartphones, or tablets. The only hardware required at the customers’ sites are PLCs and cellular modems.

Colacino Industries

Colacino Industries (formerly Newark Electric) is one of the oldest providers of automation services in New York State. Anthony DeFranco has been a Controls Project Engineer with Colacino for five years. During that time, he has helped to develop hundreds of traditional SCADA systems using a variety of remote monitoring hardware and human machine interface (HMI) software products. In 2009, the company decided to standardize on VTScada monitoring and control software from Trihedral. VTScada was recommended by a multinational distributer of pump controllers who used it as the front end of their traditional SCADA systems as well as their own worldwide hosted solution. “We started to play around in VTScada and looked at all the features available and compared those to some of the other systems that we use,” says DeFranco.

Increased Security and Uptime

In addition to lowering upfront hardware costs, there were several other factors that made a hosted system appealing. “We also found that it is a much more secure platform to work with. What we typically had in the communities where we work is a traditional SCADA system sitting on a PC, often not even workstation class PC, in the middle of a wastewater plant, or a water plant, or on someone’s desk. There are a host of issues with security and PC maintenance.” This is particularly an issue for utilities without a dedicated IT or SCADA department to actively oversee computer health. “One of the initial things we did was to get some software on these PCs so we could monitor them remotely and receive alerts when there was memory or hard drive issues, if a PC went offline, or the SCADA application crashed,” says DeFranco.

The Power of a Datacenter

“We got to that point and thought, that’s just great, but wouldn’t it be better to have this all in a datacenter with multiple sources of broadband, automated system backups, auto server, switch or router failover, enterprise class firewalls, redundant emergency generators, redundant cooling; all items that a datacenter can offer. We can also put all the devices and network communications on VPN tunnels. In fact, that’s one of the things we are still working on. We have some cell modems out there that are public IPs with built in firewalls. We are currently leasing a full cabinet in the datacenter with our primary server in the cloud environment, but we are in the process of moving everything over to our own dedicated servers.”

Universal SCADA Access

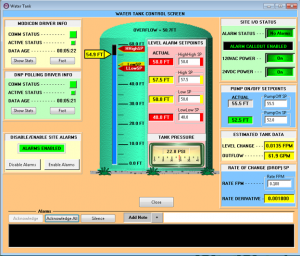

DeFranco describes other benefits to SCADA in the Cloud. “Of course, there’s the convenience to the customer to be able to look at their SCADA system from anywhere in the world.” In a hosted solution, PLCs at each customer site transmit logged data to the host via cellular modems. Authorized users log in to monitor and control their process using PCs or remote devices. “I have a customer, for example, that pretty much only uses his smart phone. He travels a lot. He can start and stop his plant, get all his data, and do everything he needs to do right from the smart phone. To him, that is the best thing ever.”

User-Driven Trending

Their chosen SCADA software also offered a unique approach to historical data that provides added convenience to users. “The way that VTScada handles trending was huge for us,” says DeFranco. “The fact that we don’t have to be there for an operator to build a historical data view, save it, and then refer to it. Typically, I would have to go there or log in remotely, sometimes restart the application to build a trend screen and add all the tags.” The Historical Data Viewer also provides a unified view of both historical and real-time data that is easily searched or exported.

Alarm and Event Management

The system makes it easy for users to navigate, sort, and acknowledge alarms. “A lot of the systems we have used do not log events. It is a big deal for us to know who turned off that pump or who hit that button or who acknowledged that alarm,” says DeFranco. “That has helped our customers a lot to determine what really happened at a particular station.”

Reporting and Compliance

“We have countless customers now on the hosted system and probably a few hundred sites. Most of them use custom reports. We picked most of those reports from VTScada’s report builder. We recently did some custom reports for a couple of our customers. These were mainly Runtime reports. We could make cells turn red when there were disparities between Runtimes. That’s something we really want to attack next. We have a lot of great ideas that we want to do with reporting,” says DeFranco.

Colacino is currently working to do more to help utilities with state and county compliance reporting. “We just had a meeting with a customer and the Department of Health. Currently, their guys are running around to each site and writing things down. Even if we gave them a report, they would have to hand write it from our report to their forms. Why not put that form in Excel and just have the SCADA system take care of that for you? The Department of Health is more than willing to look at something like that, but we have to go through an approval process before they will accept it. So, we are working towards that.”

Hosted or Installed?

Colacino currently installs both hosted and traditional SCADA systems. “We typically favor a hosted solution because of all the advantages. There is just no question; it’s the way to go. Some customers, fewer and fewer now, are resistant to that. They just want the equipment there or they don’t want the recurring cost.”

For the utility, hosted solutions help to avoid some of the nightmare scenarios associated with maintaining aging SCADA systems. “This has happened to us several times,” says DeFranco. “We had a customer with a water plant that was running really old PLCs, that had been discontinued and software that was no longer supported. The plant went down and the PLC lost its entire memory. It was a disaster. We had to go in on a Saturday and ask for the latest application files they had. They rounded up what they thought was the latest, and of course, it wasn’t. We tried to reach the previous vendor who had decided to password protect the code so we couldn’t upload the PLC. Long story short, it ended up costing the customer over $25,000 to get their plant back up and running. They had to upgrade their SCADA software, their PLC programming software, and they had to pay us to do the work. They had added flow pacing to their UV system, and of course, that was gone because it wasn’t in the latest version of the PLC software that we had. I had to go in and reprogram all of that for them. It was such a nightmare.” For hosted solutions, system maintenance is dedicated and constant, helping to eliminate losses of data, downtime, and large unexpected expenditures.

Ease of Development

For Colacino, it is far more efficient to support one centrally located SCADA application than a series of standalone systems. VTScada software was designed to be configured online meaning new features and upgrades can be rolled out to all customers without restarting the system. Integrated application version control automatically tracks all configuration changes and allows instant rollback to known good versions. “Also, the graphics library was a big deal for us. We rarely import any other graphics. Everything VTScada has is nice to look at and it is representative of what we do in water and wastewater.”

Open Connectivity

A library of native device drivers allows the system to communicate with a broad selection of customer PLCs and RTUs. “We have a product right now, actually a competitor of ours, that is scaling down and we are merging with them, if-you-will,” says DeFranco. “They have an inexpensive SCADA box which has a proprietary communications driver, so we will be working with Trihedral shortly to write that driver so we can bring that product into the system. There are many of those sites out there that we can add if we can communicate with them.” Open connectivity also allows their hosted solution to monitor more than just water and wastewater sites. “We talk to plants. We monitor generators. We even monitor our local fire department’s PLC Based Automatic Dispatch System. We mainly monitor to ensure the PLC’s health.”

Support

Considering importance of the system to their clients, support was a major consideration when selecting the SCADA software product. “Trihedral’s support is, bar none, the best out there. I talk to Doug mostly but I also work with Jennifer. They are great. I am pretty sure they know my name and my kids’ names. If I am talking to Doug about communicating with a specific device he is very knowledgeable on all of that, but if we need to talk to the guy who actually wrote that code, he just goes and gets him. You can’t have that with other vendors. That is not going to happen.” This responsiveness extends to new software features. “Early on, I handed Trihedral a wish list of things I wanted to see in the product. Six months down the road, wow, look at that. They actually added it in! That’s great.”

Plans for the Future

“There are so many more things we want to do,” says DeFranco. “We want our customers to be able to access their drawings and product data directly from the SCADA Interface. We want to give customers preventative maintenance schedules and pop-up screens to tell them when to service pumps and motors. We have so many ideas we want to incorporate. We just need to have the time to do it.”

| Try It For Yourself Download the 90-day Trial |

For More Details Tony Defranco: 315-331-1330 info@colacino.comwww.colacino.com |