Cutting Edge Software for Advanced Natural Gas Well Completion.

Improving Well Performance Through Innovation

Painted Pony Petroleum Ltd. owns 140,000 acres of the Montney Resource Play in northeast British Columbia, Canada. This area is rich with high-quality liquefied natural gas (LNG) that can be easily exported via the nearby pipeline infrastructure. As with all resource plays, economical extraction requires the kind of advanced recovery technologies for which Painted Pony has become famous. As part of their ambitious plan to develop this property, the company contracted Origin Industries Ltd. to develop a fully-featured SCADA interface for one of their remote compressor stations. The completed application uses VTScada software from Trihedral to allow operators to remotely monitor and control their sites’ wide array of equipment and finely tune the process using integrated trending and reporting tools. In this profile, Origin Industries’ CEO, Paul Cook, describes the process of developing a SCADA application worthy of their client’s advanced extraction technology.

Painted Pony is an industry leader in advanced natural gas recovery technologies. They were the first Canadian producer to apply the open-hole multi-stage ball-drop completion system in the region; increasing their average productive capability per well by 40% compared to earlier systems. Painted Pony’s five-year development plan for Montney calls for more than 240 new wells, culminating in net production volumes of 600 million cubic feet per day by 2019.

The Need For SCADA

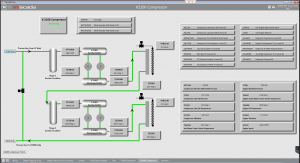

Painted Pony owns and operates three compressor stations in the Montney Formation. Each site also includes standard support equipment such as dehydrators, line heaters, inlet separators, tanks, pumps, generators, instrument air compressor skids, sales metering skid, and a motor control center (MCC).

“Painted Pony didn’t have any type of SCADA system,” says Cook. “They use a Zedi system to gather all of their historical data and perform some control.” Day-to-day monitoring and control operators relied upon a PanelView Plus unit located in the MCC that connects to the local PLC and RTU via EtherNet cabling. The panel offers minimal graphics and limited functionality with no reporting or trending. “Operators had to leave the office and go to another building to clear alarms or control the plant,” adds Cook.

VTScada Software From Trihedral

The Completed System

“Ever since I took the VTScada course and witnessed its capabilities, I have been trying to find a perfect candidate to install an application,” says Cook. “During the site’s commissioning and start-up, operations found out that there wasn’t going to be an office HMI, so they went after their site construction supervisor [who approached me]. Since Painted Pony did not have any type of SCADA system, I chose VTScada. Painted Pony was the perfect candidate.”

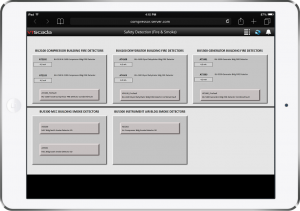

Monitoring and Control From Anywhere

Development of the new system went smoothly. “The compressor site commissioning and start-up was completed at the end of January 2015,” says Cook. “I started building the VTScada application in February and we went to site in March. Installation and commissioning was completed by the end of March 2015.” VTScada’s integrated design allowed the Origin team to implement all core SCADA components with a single installation. Built-in components such as the historian, driver library, thin clients, and alarm notification are preconfigured and remain tightly integrated over the life of the system. This approach greatly reduces risk and development time.

Future Plans

VTScada is now the main HMI operator interface supplementing the Zedi and PanelView Plus systems. The application runs on a server in the site office that also acts as an operator workstation. Additionally, the integrated thin client server allows operators to log in to monitor and control the compressor site from their home computers or mobile devices. “Before when the operators were called out, they had to drive two hours just to see what was wrong,” says Cook. “Along with that, operations use the extensive trending capability to troubleshoot process issues which all aids Painted Pony to increase efficiency.”

Cook is now considering scaling the system up to include additional sites with hot backup redundancy and automatic historian synchronization. “The goal is to put a main server in Calgary with local remote servers at each field location,” says Cook. “Each field location can also be a backup server for any other server.” This approach provides seamless protection against server failover and an always up-to-date offsite disaster backup for configuration and historical data.

About Origin Industries

Origin is an experienced and youthful Alberta based company that provides a variety of engineering services including automation, SCADA, project management, front end engineering and design studies (FEED), communications and network design and auditing, acceptance testing and commissioning, operations and maintenance technical support and training, custom applications for process optimization, equipment life cycle planning and equipment upgrade retro-fitting. Origin focuses on long-term client relationships for projects, maintenance services, and after-hours support.

| Try It For Yourself Download the 90-day Trial | For More Details Paul Cook: 403.879.1138 info@originindustries.ca originindustries.ca |