Arizona utility breaks new ground in water reuse with help from VTScada software

The Fountain Hills Sanitary District (FHSD) provides wastewater treatment for over 13,000 homes and businesses. In addition to supplying the town’s namesake fountain, its treated water irrigates local golf courses and parks. In 2000, the utility developed an innovative way to make up the short-fall during the dryer less populated summer. The process, known as aquifer storage and recovery (ASR), involves injecting excess treated water into the aquifer and recovering it when summer demand increases. ASR had never been used at such an extreme depth.

It also developed a new supervisory control and data acquisition (SCADA) application using VTScada software to monitor and control its entire operation. This application helps operators adhere to strict State regulations by tracking how much water it injects and reclaims from the aquifer at any given moment. In this article, members of the Fountain Hills team discuss how they built flexibility into the SCADA system to help them to overcome the challenges of this new technology.

Uncharted Territory

Ron Huber is the District Manager of FHSD. “The biggest challenge for us was that the process was so new. It had been done in other places but no one had gone as deep or used the same type of formations. The geology that we drilled into was a highly-cemented conglomerate and the water transmission was not through the conglomerate itself, it was through fractures. We were not aware of anyone who had done that before.” Clark Moskop is the Treatment Plant Operations Manager. “Most other ASR wells were introducing reclaimed water into alluvial types of soil. We had to inject into the deep water aquifer.”

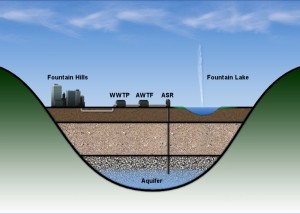

New System Overview

The FHSD team worked closely with their consultants, Hydro Systems Inc., and integrator, Applied Products Group (APG). “We expanded our wastewater treatment plant (WWTP) and constructed an advanced water treatment facility (AWTF),” says Huber. “We also created an ASR well field made up of four ASR wells. We drilled the wells to a depth of about 750 feet. The pumps were set at 450 to 470 feet with the water-bearing formations starting at the 300 foot level.” Pumping stations carry wastewater to the WWTP where it is processed and disinfected with chlorine. The effluent is then sent to the AWTF where it passes through five Pall™ Microfilters and then pumped into one of the four ASR wells. Boyce Clock is an IT Specialist with FHSD. “We have a fiber-optic network that connects the plants and ASR wells. If it fails, VTScada automatically fails over to an Internet backup. There are five other locations that use UHF radios to transmit data to a master radio that transfers it to the fiber network over Ethernet. That is the one location that uses the Internet constantly. We have two Internet providers. If we lose one, the system fails over to the other. All our connections are firewalled and we change passwords quarterly. We also have redundant back up servers in four locations for our historical data. With the layout of our building, it would take a catastrophe to knock out all five.”

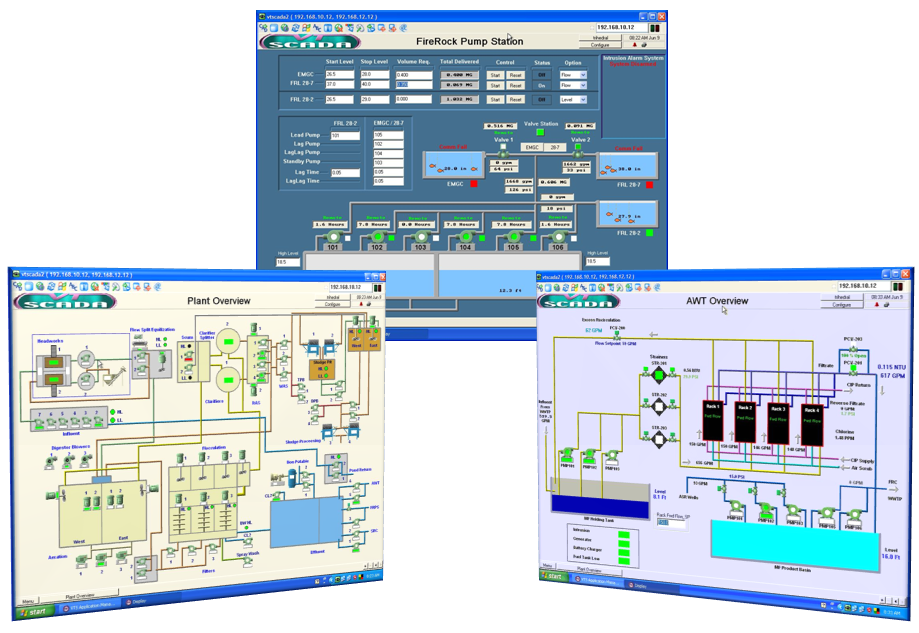

The SCADA Software Application

“It’s a complex system,” says Huber. “On any one day you could have three of the four wells receiving water for aquifer storage and a fourth recovering. You need to be able to do things like set well rates and see well levels to make sure you are not over-taxing the well either for recharge or recovery.” “This is a 24-hour plant,” says Clock. “SCADA becomes instrumental during the swing and graveyard shifts when we are sparsely manned. It’s an important back up for things like alarms. We treat effluent like a valuable commodity; we don’t like spilling it. So it is important to have the safeguards that a SCADA system provides.” VTScada software was one of two monitoring and control products being used in various parts of the old system. The team decided to standardize on one. “VTScada was a stable platform that came with drivers we needed to interface with our existing monitoring and control equipment,” says Moskop. The new VTScada application now runs the entire facility for plant operations, aquifer storage and recovery and effluent distribution. “Operators monitor the injection and recovery rates to and from the wells,” says Moskop. “They monitor head pressure as well as well performance based upon draw-down or increasing water level in the injection mode.”

Building Flexibility into the SCADA System

Since ASR was so new, Huber wanted to ensure that the completed system could grow as they learned more about it. “We started with an idea of how it would operate,” says Huber, “but we wanted it to be flexible enough that we could make changes in the future. As it turns out, it was a good thing we did.” “Originally, we intended to run the system from late fall to mid spring and put it into hibernation during the summer. However, when we put the system into hibernation that first summer we had issues with bio-fouling of the wells. We had to chemically clean each well to remove the bacteriological growth. This growth is not detrimental to the quality of the water but merely to the mechanical operation of the well. Through consultation with our hydro geologist, our engineer and our operations staff, we decided that we needed to run the system all year. Constantly exercising the wells in either direction controls the problem.” “An aquifer is a living breathing creature.” Clock points out. “So it is also very important to briefly reverse the flow three times a day for up to 15,000 gallons. This helps to keep our casings clean. “The VTScada system does a very good job of allowing us to monitor the well’s performance during injection and recovery,” adds Moskop. The operator interface also changed. “We thought we needed separate display screens for everything,” says Moskop. “VTScada allowed us to add more information to fewer screens which means less page flipping and smoother operation.” These changes were just the beginning. “We always seem to be in various stages of construction at the plant,” continues Moskop. “We redid our chlorine system. We added clarifiers, an automated blower control system and UV disinfection. VTScada is a very good platform in that it allows us to copy what we have, retag it and move forward. The ease of use is great.” The District also decided to add a fifth ASR well. “All of our golf course lakes are basically reservoirs,” says Clock. “In addition to supplying the town’s fountain, Fountain Lake also irrigates the park. In the summer, we have a considerable decrease in population so we cannot produce enough water to maintain the level in this reservoir so we have to recover heavily from the wells. However, summer is also the best time to rehabilitate our wells. When a well is offline, we can only produce three quarters of our normal output. The new well will help take some of the pressure off of supplying Fountain Lake.” “This well is almost twice as deep as the others. It has only one line for delivery and injection; the others have separate lines. The four existing wells pump up to a two million gallon reservoir. This one will pump directly from the AWTF and will have the choice of pumping to the product basin where it can be sent to various reuse locations or into Fountain Lake.”

Technical Support

Huber points out that technical support at Trihedral, the makers of VTScada, is another important factor in keeping the application stable and flexible. “One of the things I hear a lot from operators is that when they have a problem, they always receive help very quickly and their problems are solved in a short period of time.” “Their support is second to none,” says Moskop. “There are always little changes that come up. They are very receptive and iron them out in a timely manner.” Clock agrees. “They have been tremendous in their knowledge and helpfulness. They have been instrumental in working with Wes Suderman of APG who handles our integration.”

Conclusion

Considering the steep learning curve and experimental nature of their ASR process, Huber is pleased with what they have accomplished. “When you go back and see what we did, it is remarkable that we made it this far.” “It’s been a very robust SCADA system,” adds Moskop. “It’s easy to operate. It gives us a very good idea of what we have injected and what we are recovering. Our operators are typically not IT people by trade but they have been able to really grasp the concepts and move forward. They have a lot of confidence in their ability to use the system.”

| Try It For Yourself Download the 90-day Trial | Download the Case Study as a PDF |

Images reproduced with the permission of the Fountain Hills Sanitary District.